Silicon Carbide Heat Exchanger for Corrosive Media

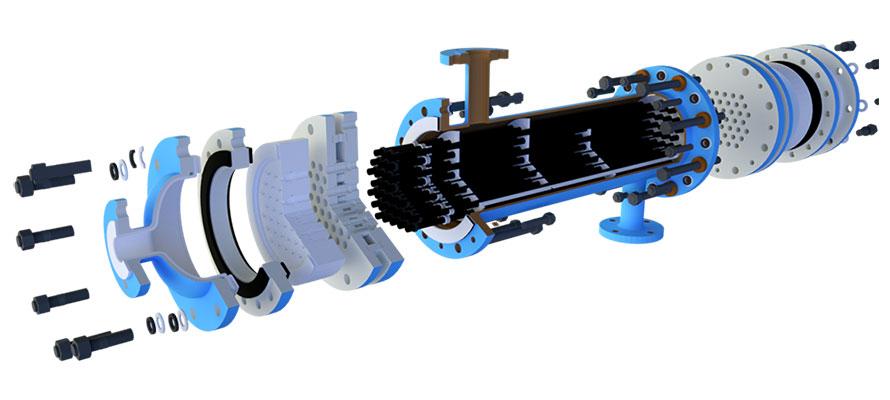

Silicon carbide heat exchangers for corrosive media are used in chemical (pharmaceutical, pesticide, fine chemical, organic, inorganic) process systems for heat exchange of strong corrosive media. A silicon carbide heat exchanger can withstand highly corrosive mediums, such as high concentrations of sulfuric acid, nitric acid, phosphoric acid, hydrobromic acid, hydrofluoric acid, sulfonic acid, mixed acid, strong alkali, organic solvent, oxidizer and other highly corrosive acids. The pressure free sintered silicon carbide material is the only ceramic material that cannot be corroded by hydrofluoric acid. Our ultra-large silicon carbide heat exchanger can withstand a vapor pressure of 16kg and a temperature of 210℃. The product uses double tube sheets, with the carbon steel tube sheets featuring a high pressure and high temperature resistance. The other tube sheets use a special carbon steel (PTFE reinforced carbon steel) to eliminate deformations caused by an oversized PTFE sheet. In addition, each silicon carbide tube is sealed respectively, using a sealing nut, which meets the sealing requirements for a large tube sheet and facilitates equipment maintenance.

Parameters:- Maximum design temperature: 300℃

- Maximum temperature in-service: 250℃

- Maximum design pressure: 1.6MPa

- Maximum pressure in-service: 1.3 MPa

- Maximum heat transfer area: 300m2

- Maximum heat transfer area in-service: 70m2

- Maximum design diameter: 1200mm

- Maximum diameter in-service: 900mm

| DN | Number of tube | Length of tube (mm) | |||||

| tubeQty | 1000 | 1500 | 2000 | 2500 | 3000 | ||

| 100 | 8 | 0.35㎡ | 0.53㎡ | 0.70㎡ | 0.88㎡ | 1.06㎡ | |

| 150 | 22 | 0.97㎡ | 1.45㎡ | 1.93㎡ | 2.42㎡ | 2.90㎡ | |

| 200 | 42 | 1.85㎡ | 2.77㎡ | 3.69㎡ | 4.62㎡ | 5.54㎡ | |

| 250 | 64 | 2.81㎡ | 4.22㎡ | 5.63㎡ | 7.03㎡ | 8.44㎡ | |

| 300 | 96 | 4.22㎡ | 6.33㎡ | 8.44㎡ | 10.55㎡ | 12.66㎡ | |

| 350 | 140 | 6.15㎡ | 9.23㎡ | 12.31㎡ | 15.39㎡ | 18.46㎡ | |

| 400 | 187 | 8.22㎡ | 12.33㎡ | 16.44㎡ | 20.55㎡ | 24.66㎡ | |

| 450 | 241 | 10.59㎡ | 15.89㎡ | 21.19㎡ | 26.49㎡ | 31.78㎡ | |

| 500 | 301 | 13.23㎡ | 19.85㎡ | 26.46㎡ | 33.08㎡ | 39.70㎡ | |

| 600 | 434 | 19.08㎡ | 28.62㎡ | 38.16㎡ | 47.70㎡ | 57.24㎡ | |

| Corrosive medium | Temperature ( ℃) | Corrosion rate mg/cm2.Y | Corrosion rate mm/Y | |

| 98%H2SO4 | Sulfuric acid | 100 | 0.98 | 0.0032 |

| 54%HF | Hydrofluoric acid | 25 | 0.06 | 0.0002 |

| 50%NaOH | Sodium hydroxide | 100 | 1.25 | 0.0040 |

| 45%KOH | Potassium hydroxide | 100 | 0.04 | 0.0001 |

| 70%HNO3 | Nitric acid | 86 | 0.04 | 0.0001 |

| 37%HCL | Hydrochloric acid | 25 | 0.07 | 0.0002 |

| 10%HF&HNO3 | Hydrofluoric acid & nitric acid | 25 | 0.05 | 0.0002 |

| 10%HF&HNO3 | Hydrofluoric acid & nitric acid | 120 | 1.25 | 0.0040 |

- We use ASPEN software and our extensive practical experience in order to ensure the products are smaller in size and cost-effective, as well as allow us to guarantee the technical performance.

- Taking high temperature, high pressure and high hazard medium environments in the industry into consideration, we have designed a highly reliable seal structure (the invention patent for the double tubesheets silicon carbide heat exchanger) to ensure that there is no cross contamination between the treated medium and the service medium.

- We use pressure free sintered silicon carbide materials developed by the Chinese Academy of Sciences for production that feature ultra-fine particles and a high purity.

- We use PTFE & fluorine rubber for sealing and each pipe is double sealed.

- We use the polytetrafluoroethylene & glass fiber reinforced tube sheet and cover to ensure that the silicon carbide tube installed on the PTFE tube sheet won’t break through deformation. In addition, due to the adequate compression force of the sealing ring, the equipment will not leak when the temperature changes.

- We use PTFE baffles and pull rods to protect each silicon carbide tube from abrasion.

- Backed by international, advanced technology and extensive service experience,we use three gaskets and double sealing technology to ensure that the equipment will operate normally, even after long term usage.

- Special tube sheet structure: there is an outlet on the tube sheet to ensure that the machine will discharge the water and materials on the shell and tube side when the equipment shuts down. This design prevents damage to the silicon carbide tube caused by frozen water inside, making it more conducive to overhaul.

- We carry out strict quality inspection—hydraulic pressure test of 6 barg at least. We also carry out a temperature and pressure test at 150℃ and 5 barg to ensure that the equipment works well under customer working conditions.

- Before leaving the factory, every silicon carbide heat exchanger will go through the steam pressure and water pressure test. After passing all tests, the silicon carbide heat exchanger will be sent to the customer.

Wuxi Innovation Technology Co., Ltd.

Add.: 19#,Jinhui Road,Huishan District, Wuxi City, Jiangsu Province, China.

Contacts: Peter Tsao

Moblie: +86-18114106791

E-mail: cb@innovationtec.cn

WhatsApp: +86-13813843213

SiC Condenser and Chiller

SiC Condenser and Chiller Sulfuric Acid Dilution System Heat Exchanger

Sulfuric Acid Dilution System Heat Exchanger Sulfuric Acid Concentrator

Sulfuric Acid Concentrator